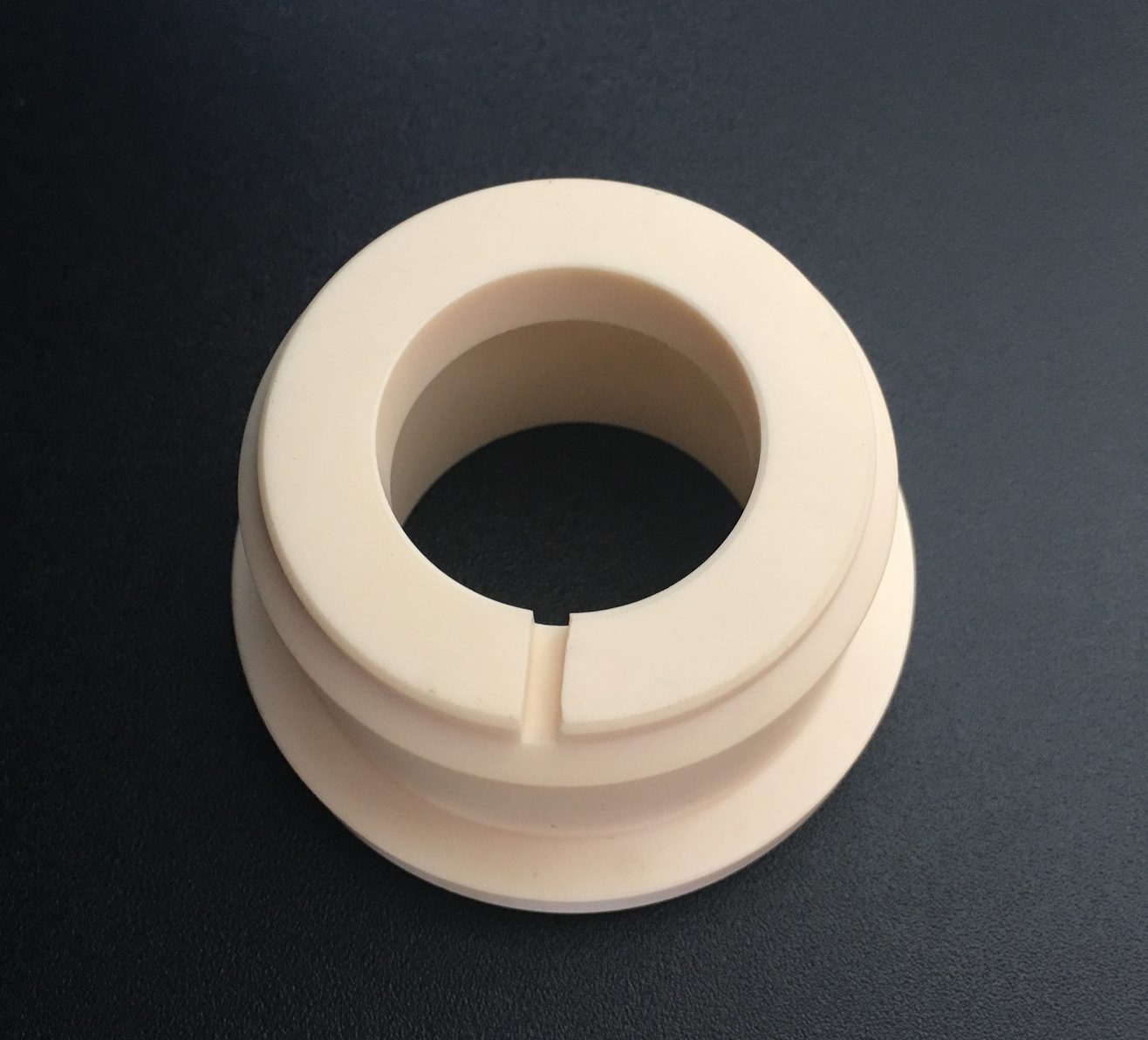

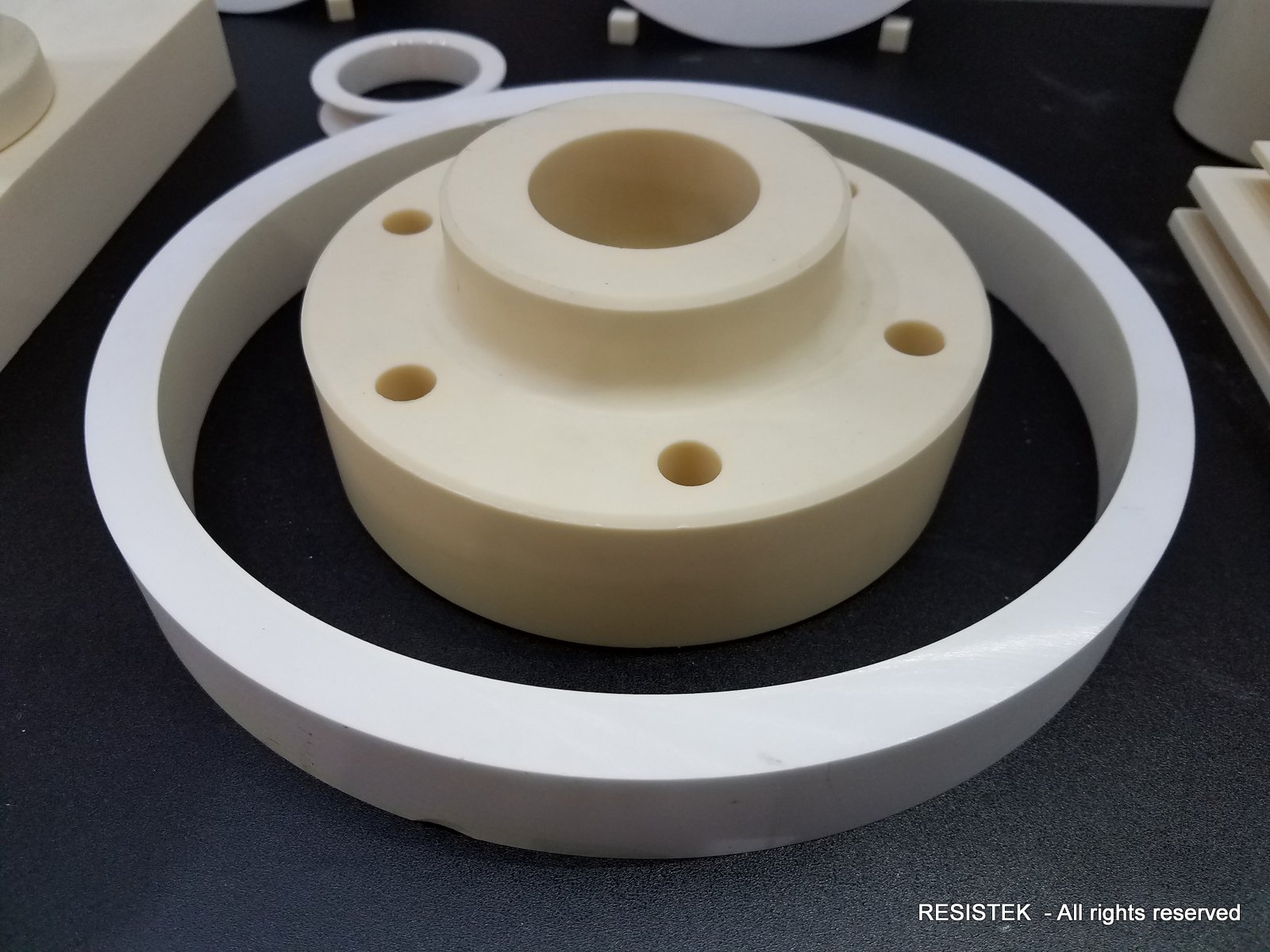

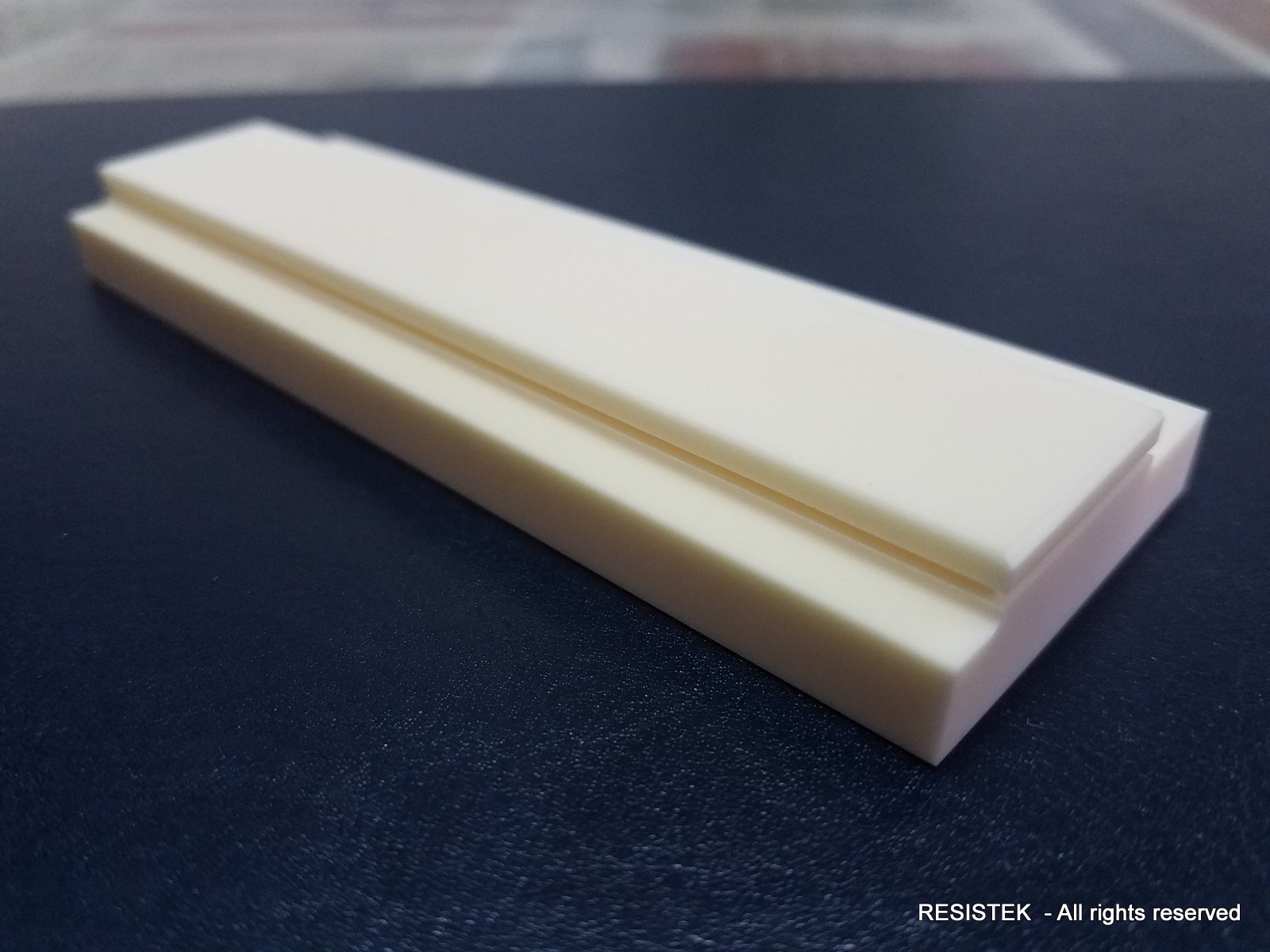

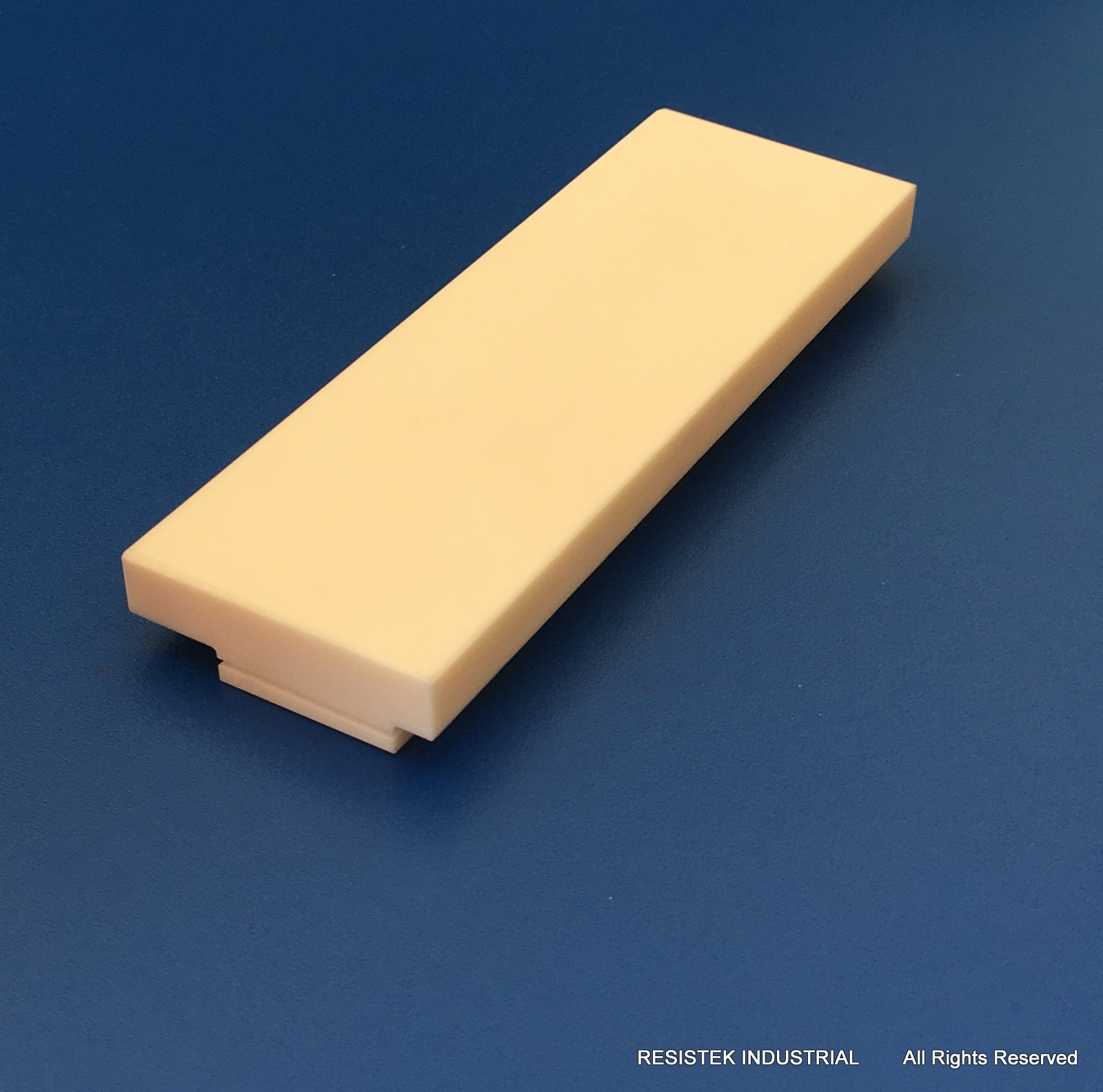

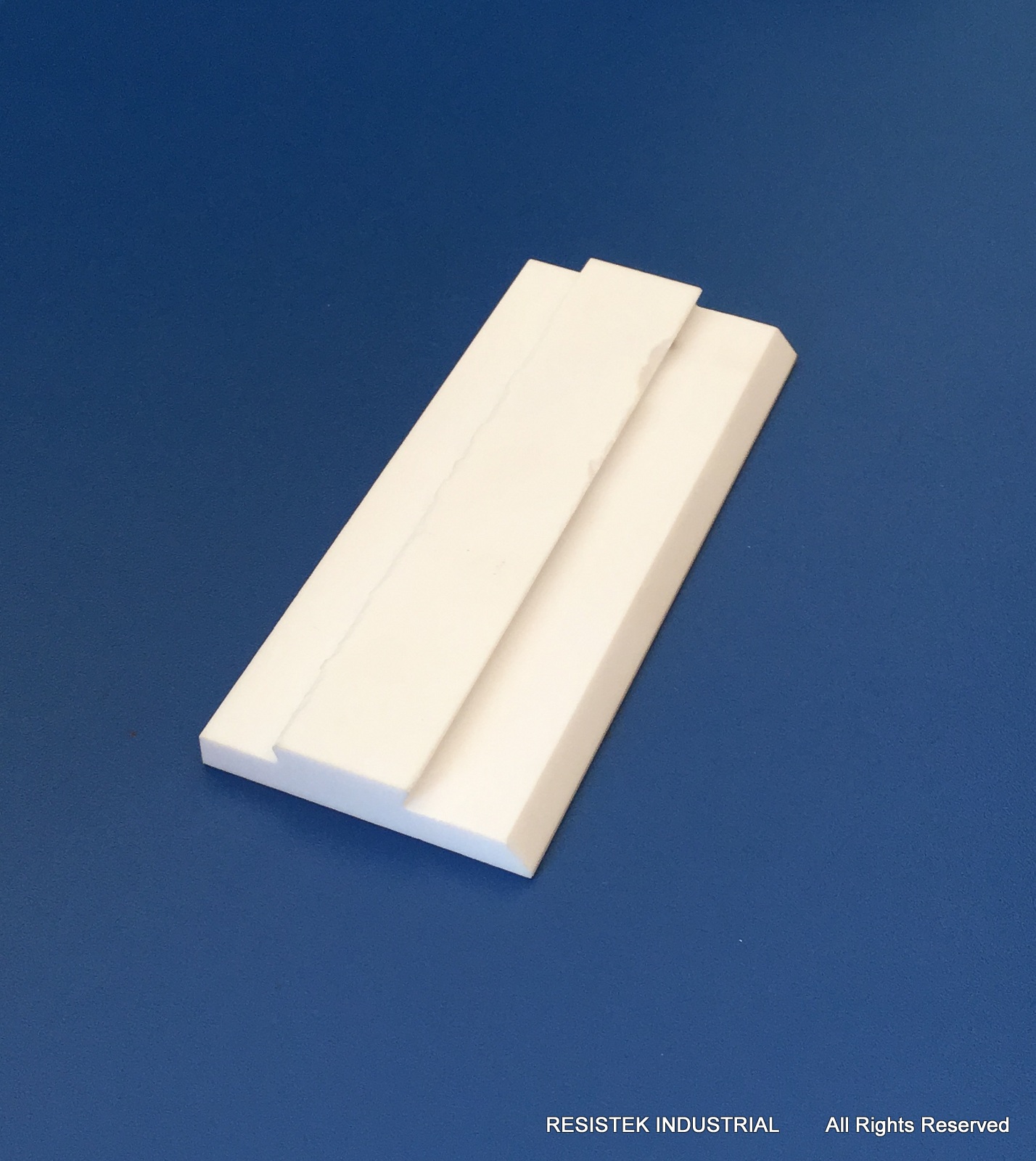

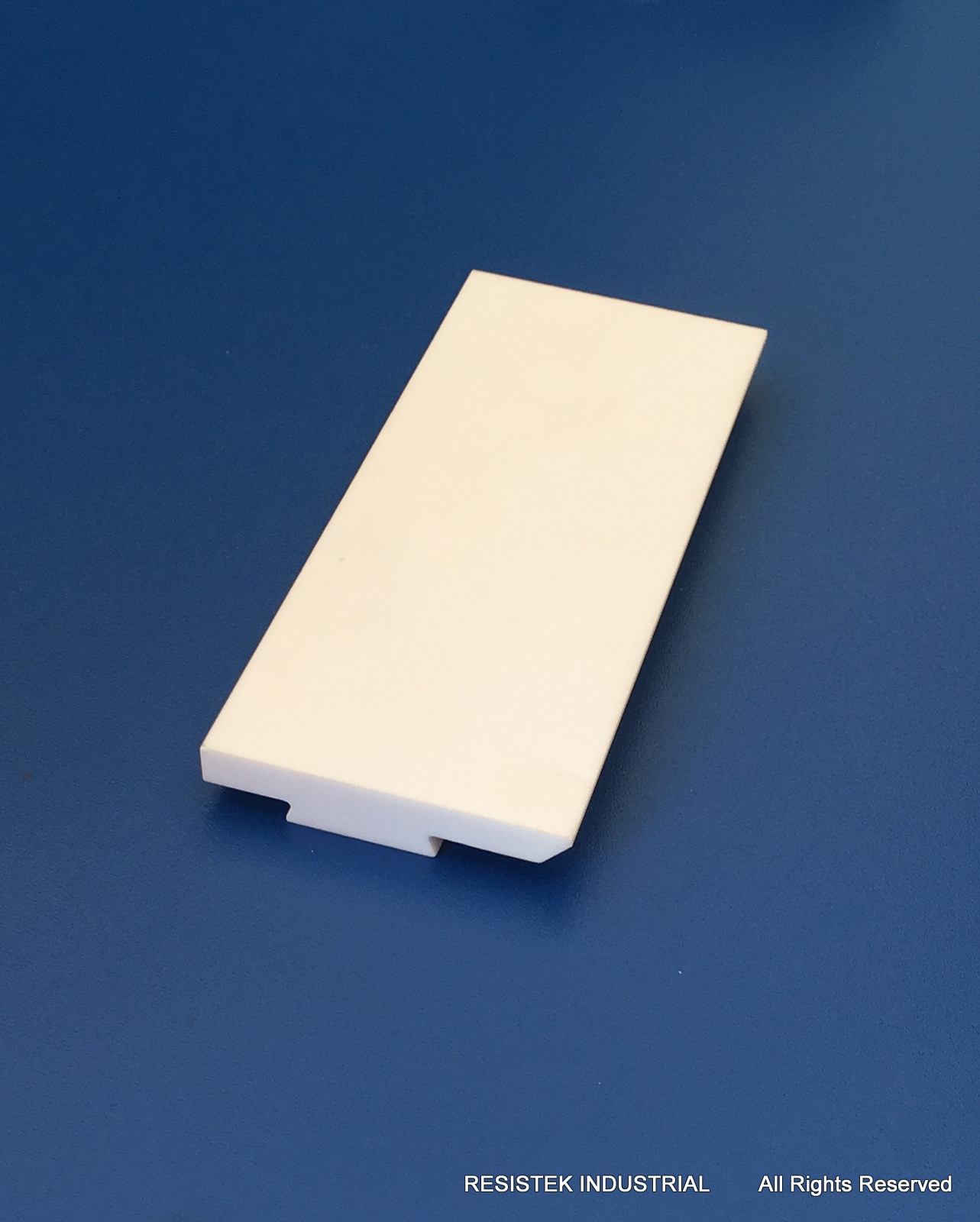

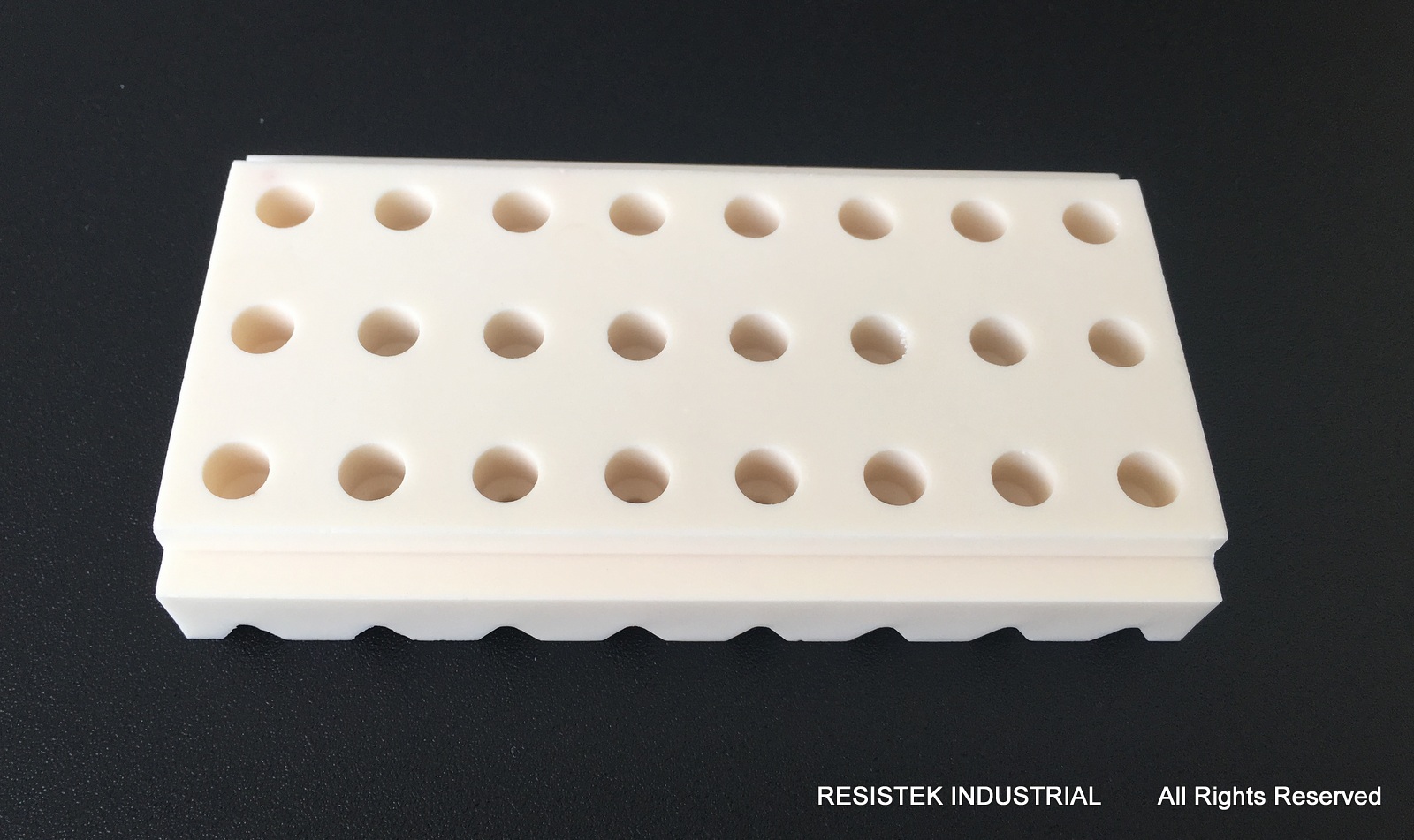

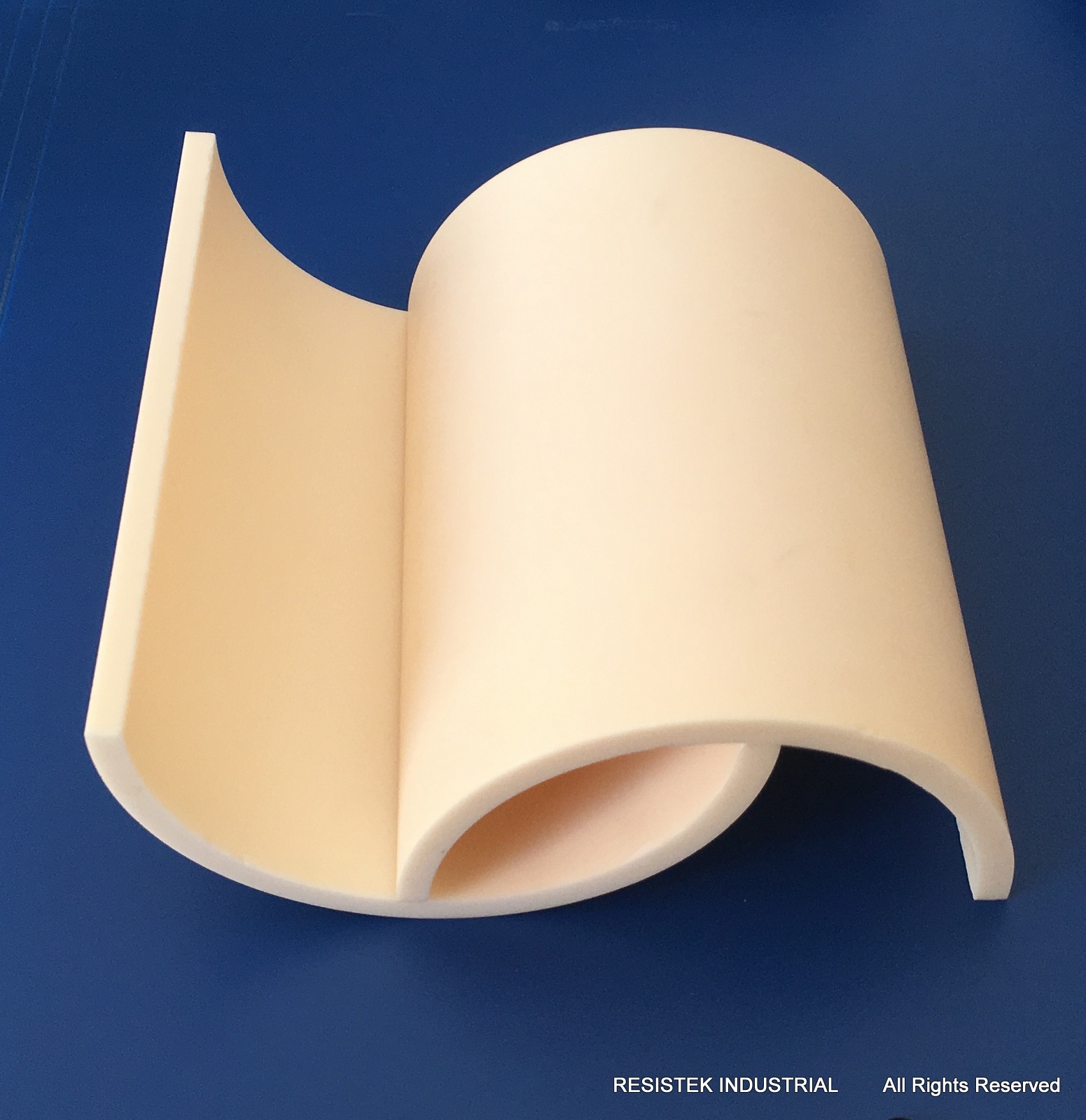

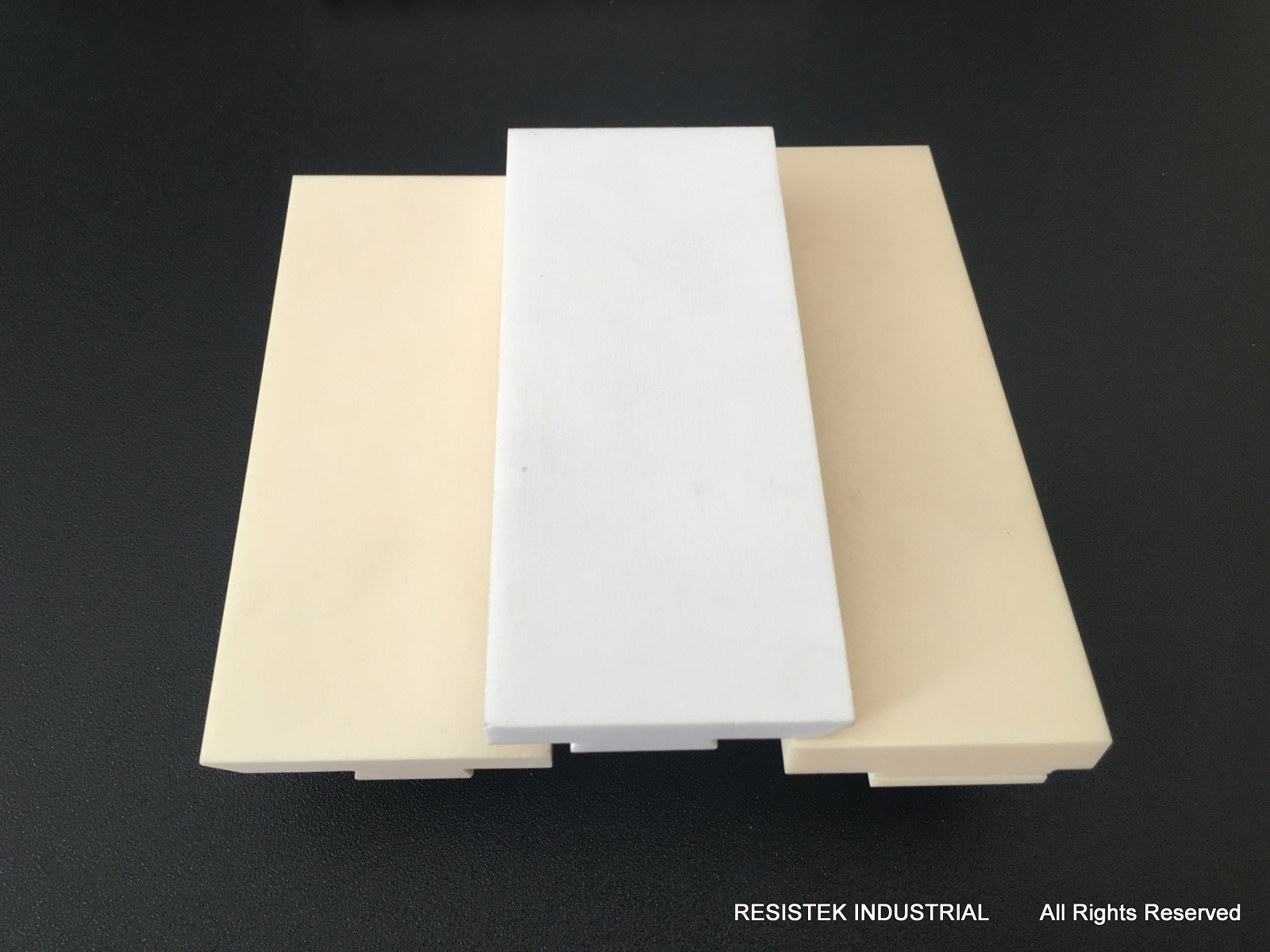

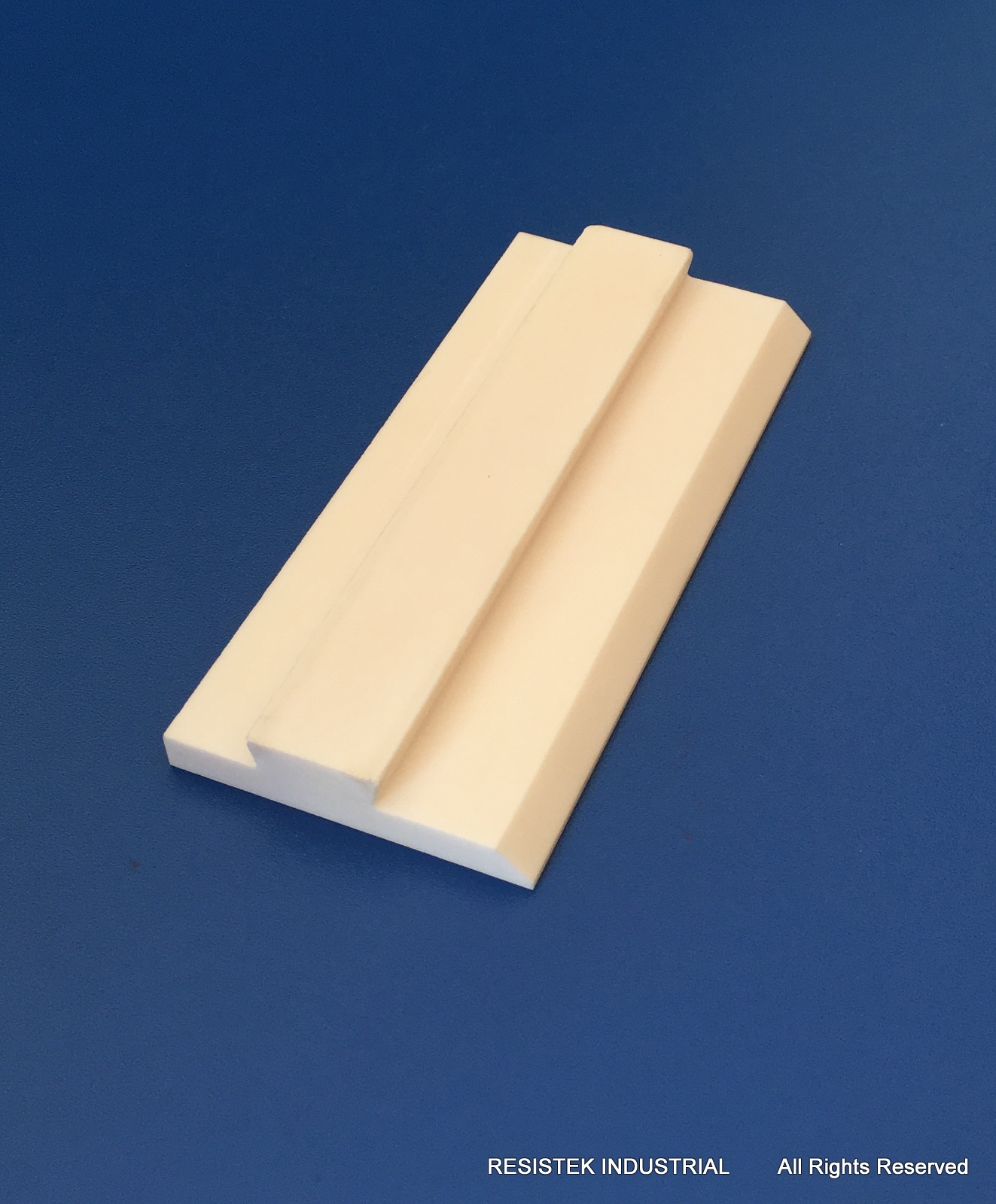

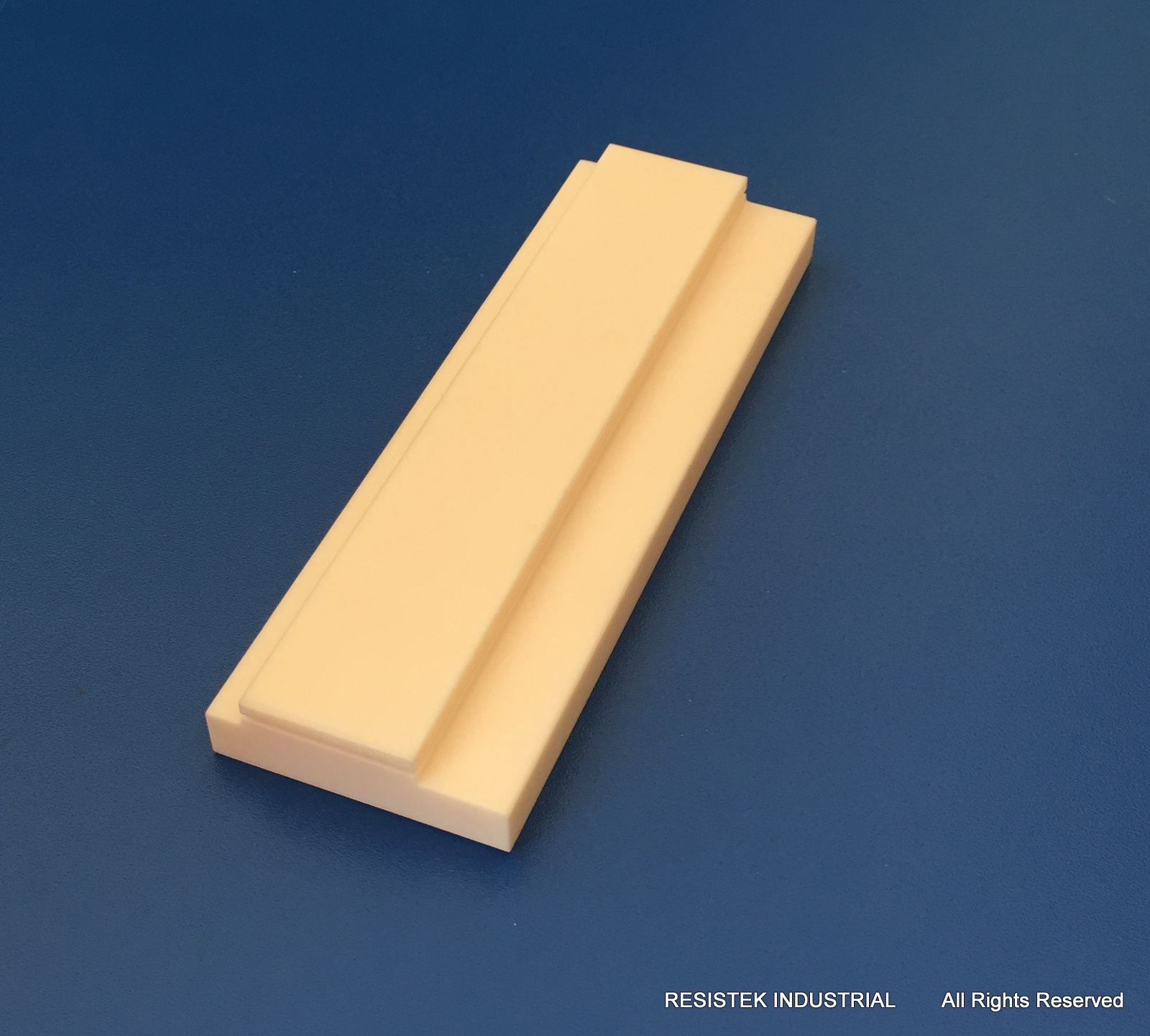

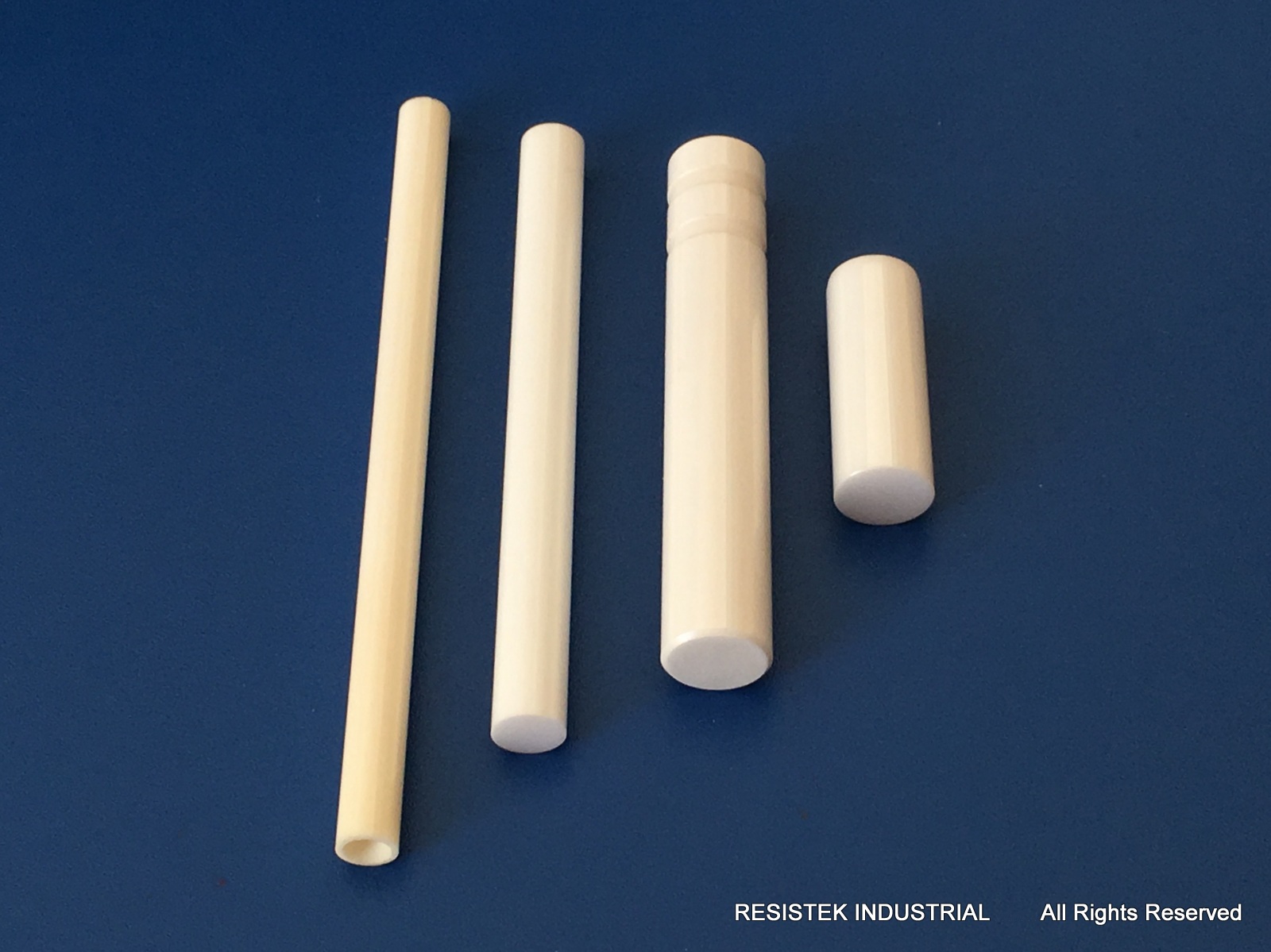

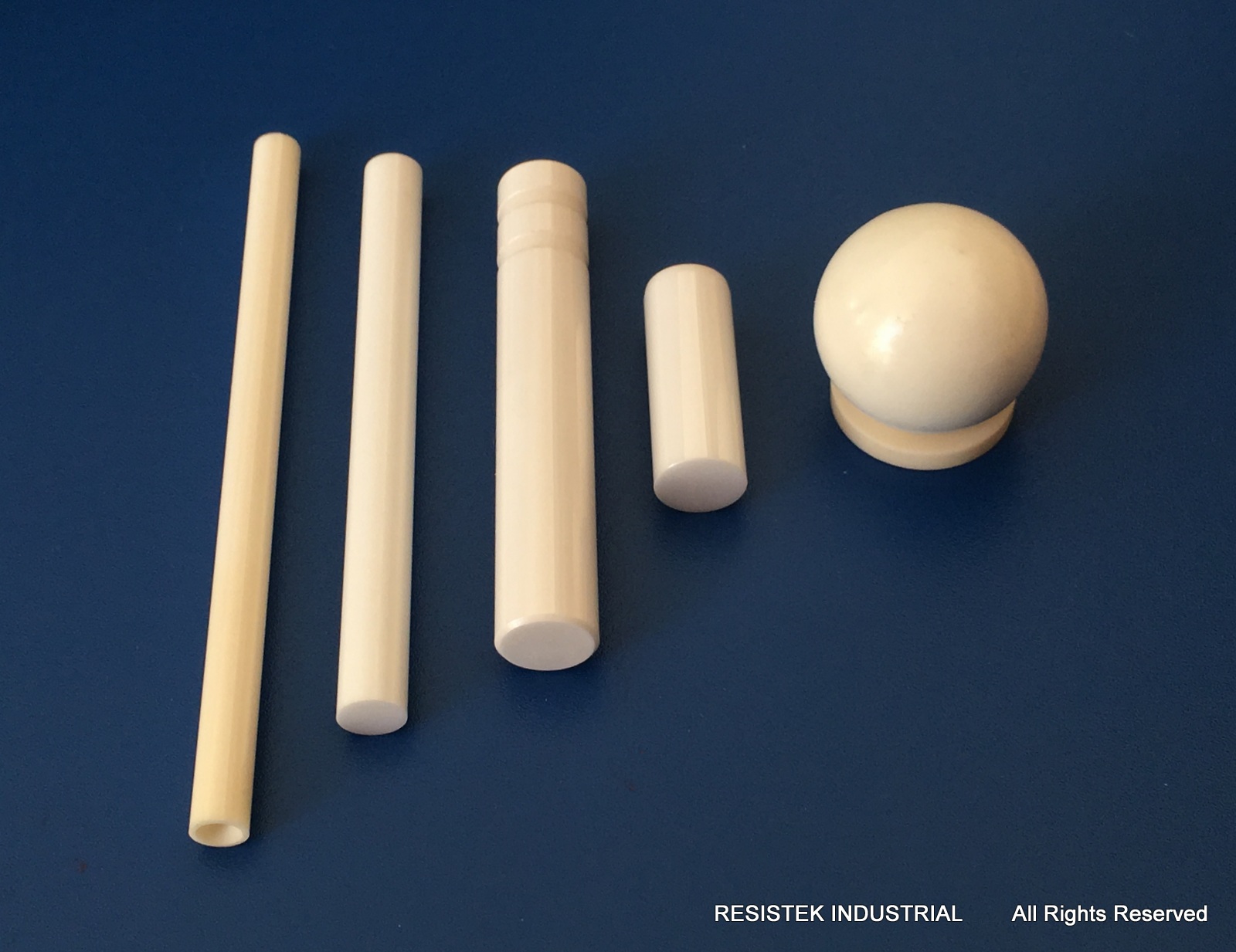

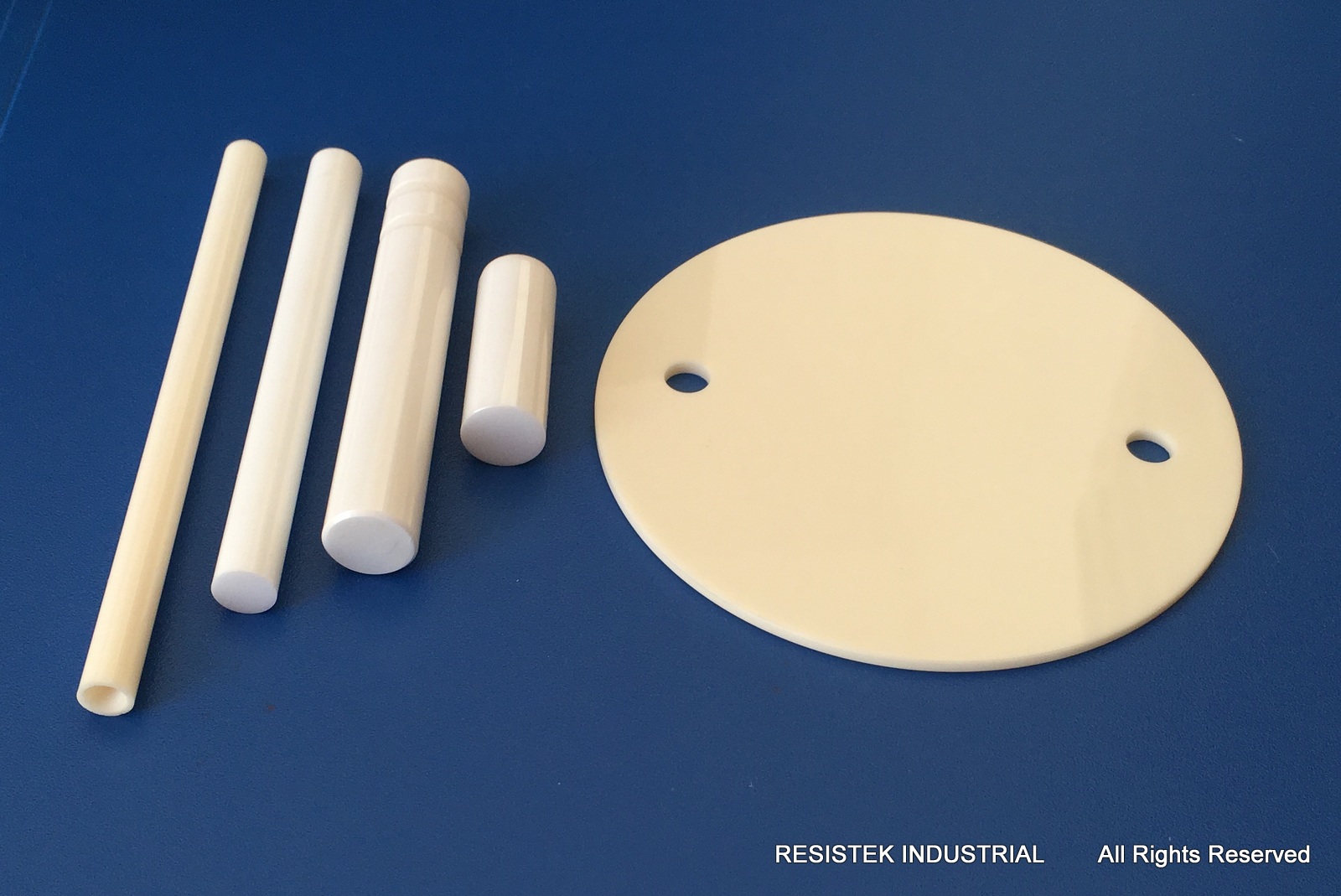

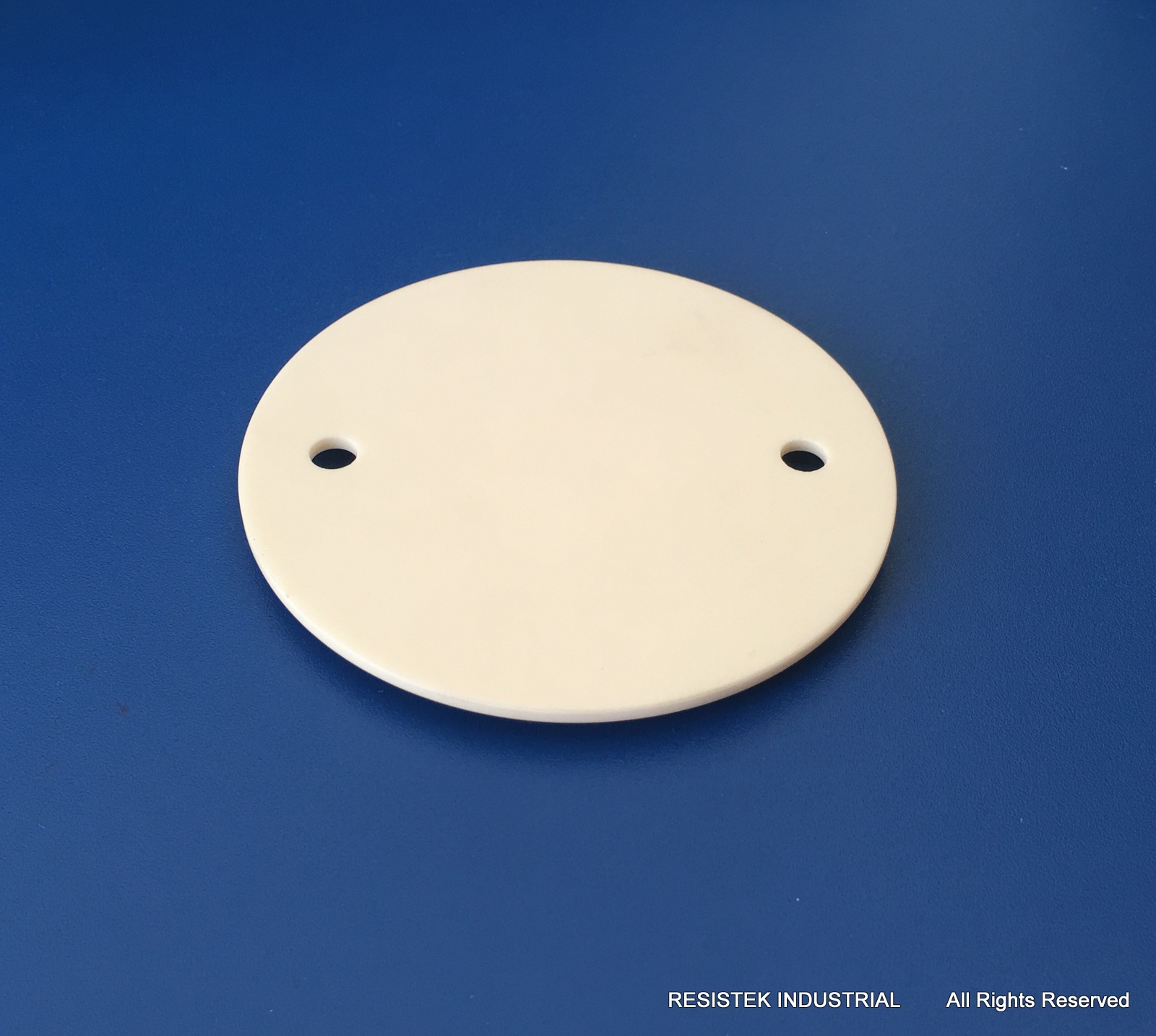

RESISTEK manufactures a big range of silicon nitride and zirconia advanced ceramic weld location and control pins. These are used in the metal forming industry to allow precise welding of nuts to sheet metal.

Silicon nitride based weld location pins possess a number of characteristics, such as excellent mechanical, thermal and chemical properties, making them ideal in metal forming applications.

Zirconia based weld location pins excel where their greater toughness is required, such as when severe impact is a possibility. They have excellent wear resistance, however they are not recommended where thermal shock may occur. Also, they are double the weight of an equivalent silicon nitride based weld location pin.

The tables below show our range of standard weld pins. However, we make a whole range of none standard sizes, so please contact us with your enquiry.

Standard Weld Location Pins–Technical Information

| Part No. | NUT SIZE | A | B | C | D | E | F | G | R |

|---|---|---|---|---|---|---|---|---|---|

| RISN 050060 | M5 | 6 | 2 | 12 | 1 | 6.0 | 7.5 | 15 | 15 |

| RISN 060070 | M6 | 7 | 2 | 12 | 2 | 7.0 | 9.5 | 15 | 15 |

| RISN 060078 | M6 | 7 | 2 | 12 | 2 | 7.8 | 9.5 | 15 | 15 |

| RISN 060088 | M6 | 10 | 3 | 12 | 2 | 8.8 | 8.0 | 15 | 15 |

| RISN 080090 | M8 | 10 | 5 | 14 | 2.5 | 9.0 | 7.5 | 15 | 12.5 |

| RISN 100110 | M10 | 12 | 4 | 16 | 2.5 | 11.0 | 8.0 | 15 | 12.5 |

| RISN 120130 | M12 | 13 | 4 | 18 | 2.5 | 13.0 | 8.0 | 15 | 12.5 |